Spray-On Chrome Finish Services

Durable & Flawless Chrome Finish Solutions for Prototypes, 3D Models & Production Parts

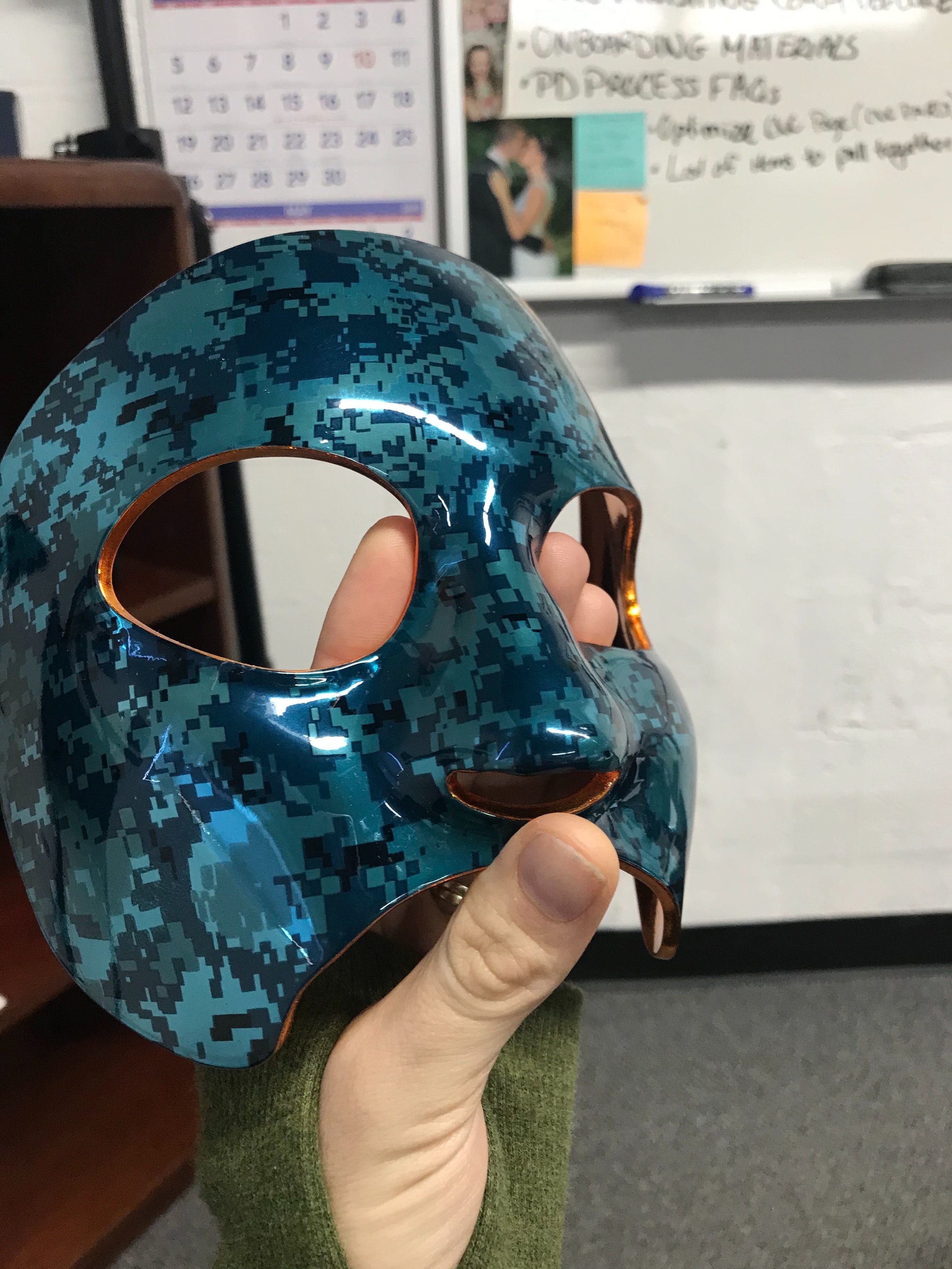

There’s nothing quite like the shiny, reflective finish of chrome. Whether used for decoration or to accent a component or product feature, eye-catching chrome makes prototypes, 3D models, and finished products stand out. A spray-on chrome finish is an efficient and beautiful option for achieving a high-end look.

As part of our comprehensive selection of painting and coating services, Empire Group can apply high-quality, spray-on chrome finishes on simple or complex pieces. We use a specialized process that’s durable, custom tintable, and looks like the real thing.

Take a closer look at the advantages of choosing Empire Group’s spray-on chrome finishing and our signature three-step process.

Why Choose Empire Group's Spray-On Chrome Finishing?

Spray-on chrome finishing is a great choice for experimenting with aesthetics or signature colors for models, prototypes, or limited edition versions of a standard product. It also adds a realistic touch to the look of miniaturized products and trade show models. Empire’s spray product creates a realistic chrome finish with a smooth, gleaming layer on top of machined parts, prototypes, 3D-printed parts, and more.

The spray-on process is faster than conventional alternatives and provides more comprehensive coverage of intricate designs without slowing down production, making it cost-effective too.

This finishing process is compatible with a range of non-absorbent materials and substrates including vinyl, polypropylene, polycarbonate, rubber, and even soft polymers. Extensive tests have proven its superior adhesion properties can withstand cutting, tearing, bending, and squeezing.

Empire is committed to excellence in customer service as well as prototype and low-volume manufacturing, assembly, and finishing. Our company is ITAR registered, ISO 9001 and ISO 27001 certified, and we use state-of-the-art application methods to further guarantee the quality of our products and services.

Understanding Our Spray-On Chrome Finishing Process

Our high-quality chrome finish is far more than a single coat of metallic spray. Every workpiece goes through a unique three-step process to ensure complete coverage and a metallic shine that looks just like chroming and stays put with use over time. Here’s how it works:

Industries Served

Ready to Discuss Your Chrome Finishing Needs? Contact Us for a Free Consultation

Prepare your small-batch products, prototypes, and tradeshow demos for display, testing, or distribution with a beautiful spray-on chrome finish. Empire Group's professional chrome spray process is an efficient, cost-effective, and beautiful finish that gets noticed and remembered in any setting.

Request a quote for pricing information or schedule a free consultation to start your project.