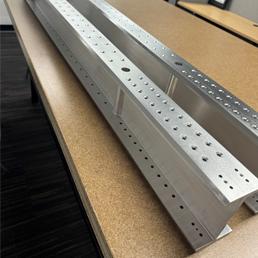

CNC Machining Services • Custom Prototypes & Parts

Precision CNC machining services for prototypes, mold, and production parts.

At Empire Group, we specialize in precision CNC machining services for customers in the aerospace, automotive, defense, and medical industries. Our highly experienced machine programmers and operators can meet a range of project requirements, including complex geometries, tight tolerances, and production-grade materials. Regardless of your needs, our problem-solving capabilities enable us to deliver precise, repeatable parts with optimal quality and speed.

Precision CNC Machining Capabilities

CNC machining is a versatile manufacturing method that is suitable for a wide range of applications. At Empire Group, our precision CNC machining capabilities include rapid prototyping, short-run production, and rapid tooling.

CNC machining facilitates the quick and accurate production of prototypes to aid in the design validation process.

Short-run Production

CNC machining can efficiently produce small batches of parts with optimal accuracy and cost-effectiveness.

Rapid Tooling

CNC machining can be used to precisely create molds, fixtures, and dies with intricate details to ensure consistent and high-quality outputs.

The Benefits of CNC Machining for Rapid Prototyping

CNC machining has grown in popularity for rapid prototyping due to its ability to produce complex geometries with high precision. CNC machining is especially ideal when you need a prototype that looks, feels, and functions similarly to the finished product. In addition to being an efficient way to validate product designs, CNC machining offers various other benefits when it comes to rapid prototyping. These benefits include:

Structural Integrity. CNC machining is compatible with various strong materials, resulting in prototypes that feature a high degree of durability and structural integrity.

Accuracy. Because CNC machines are fully automated, they are capable of producing prototypes with extreme dimensional accuracy and precision.

Speed and Easy Modification. The automated nature of CNC machining also makes it very fast. CNC machines can produce prototypes in a matter of hours. Because the process offers shorter lead times, engineering teams can quickly evaluate prototypes and make any necessary design modifications to make the product function as desired.

Wide Range of Material Options. CNC machining is compatible with numerous material options. This makes it easier for product developers to evaluate the cost, performance, and appearance of parts made with different materials.

Product Size. CNC machining can produce prototypes of various sizes, ranging from a few inches to several feet.

CNC Materials Selection

At Empire Group, our CNC machining services are compatible with a diverse range of materials, including numerous metals, plastics, and composites. If you don’t see the material you’re looking for, we can also source various materials upon request.

Our material options include:

-

Aluminum: 6061, Mic 6 (cast plate)

Brass: 360

Copper

Milled Steel: 1018, 12L14

Stainless Steel: 303,304,316, 17-4

Tool Steels: A2, D2, 4140, P20

Titanium: 6AL Alloy

-

ABS

Acrylic

Delrin/ Acetal

Ertalyte

G-10 Epoxy-Glass

LDPE/HDPE

Lexan

Nylon

PEEK

Polycarbonate

Semitron

Teflon

UHMW

Ultem

-

450/460 Thermoform Models

Brass: 360

REN Board

Defense Procurement Manager

"First I would like to say, Empire did an exquisite job on the TEER monitor items, all parts were spot on, came in before the due date and communication has been great!"

Defense Procurement Manager

Contact Us for Custom CNC Machined Prototypes and Production Parts

Empire Group’s expert CNC machining capabilities allow us to produce tight-tolerance prototypes, low-volume parts, and tooling from a range of raw materials. We are ITAR-registered, as well as ISO 9001 and ISO 27001 certified to ensure our customers receive the highest quality components with fast turnaround times and unparalleled craftsmanship.

For more information about our custom CNC machining services, or to get started on your next project, request a quote today.

LEARN MORE ABOUT USIndustries Served